#Electronics System Design and Manufacturing

Explore tagged Tumblr posts

Text

How to Overcome Common Challenges in PCB Assembly for ESDM Projects

In the dynamic world of Electronics System Design and Manufacturing (ESDM), success hinges not just on innovation, but also on precise execution—especially during PCB (Printed Circuit Board) assembly. As projects become more complex, so do the challenges faced during this critical phase. At Aimtron, we’ve seen firsthand how addressing these challenges early leads to smoother project flows, faster time-to-market, and higher quality products.

In this blog, we’ll dive into the most common PCB assembly challenges for ESDM projects and share proven strategies to overcome them.

1. Component Sourcing and Availability

The Challenge: Global supply chain disruptions, component shortages, and long lead times can delay PCB assembly, jeopardizing project timelines.

The Solution:

Early BOM Finalization: Lock your Bill of Materials (BOM) early and validate components for availability.

Multiple Sourcing Strategies: Partner with trusted suppliers and maintain alternate part options.

Inventory Management: Use just-in-time (JIT) inventory systems while keeping a buffer for critical components.

Leverage Aimtron’s Global Network: Our established supplier partnerships help mitigate shortages and ensure timely procurement.

2. Design for Manufacturability (DFM) Issues

The Challenge: PCBs designed without considering manufacturing capabilities often lead to rework, delays, and higher costs.

The Solution:

Early DFM Review: Engage manufacturing experts during the design phase for feedback on layout, spacing, and assembly feasibility.

Simulation and Validation: Use advanced tools to simulate manufacturing processes.

Collaboration with Aimtron's Engineering Team: Our design-for-assembly (DFA) and DFM services ensure your PCB designs are optimized for production from day one.

3. Soldering Defects

The Challenge: Soldering errors like cold joints, bridging, and voids can compromise the reliability of PCBs.

The Solution:

Precision Process Control: Strictly monitor solder paste application, reflow profiles, and hand-soldering techniques.

Quality Training: Continuous training of assembly staff in IPC standards.

Automated Optical Inspection (AOI): Aimtron uses AOI and X-ray inspection systems to detect and correct soldering issues in real-time.

4. Electrostatic Discharge (ESD) Damage

The Challenge: ESD can silently destroy sensitive electronic components during handling and assembly.

The Solution:

Strict ESD Protocols: Implement ESD-safe workstations, grounding systems, and employee training.

Continuous Monitoring: Use ESD monitoring devices to ensure protection throughout the facility.

Certified ESD-Safe Facilities: At Aimtron, our facilities meet global ESD standards to protect your PCBs during every step of assembly.

5. Maintaining Quality in High-Mix, Low-Volume Production

The Challenge: ESDM often requires the assembly of many different PCBs in small batches, making consistency a challenge.

The Solution:

Flexible Manufacturing Systems: Deploy agile production lines capable of quick changeovers.

Strong Documentation Practices: Use detailed work instructions and traceability systems.

Continuous Improvement Programs: Aimtron’s commitment to Kaizen ensures quality is never compromised, no matter the batch size.

6. Thermal Management During Assembly

The Challenge: Components that generate significant heat or require special handling (e.g., BGAs, high-power ICs) can complicate the assembly process.

The Solution:

Proper Heat Profiling: Develop accurate reflow oven profiles tailored to PCB thermal characteristics.

Use of Thermal Reliefs: Design PCBs with thermal relief pads to assist in proper soldering.

Thermal Simulation: At Aimtron, we utilize advanced modeling to predict and manage thermal challenges during assembly.

Conclusion

Navigating the complexities of PCB assembly in ESDM projects requires more than technical know-how—it demands a strategic, proactive approach. From sourcing components to ensuring ESD protection and optimizing for manufacturability, every step is critical.

At Aimtron, we don’t just assemble PCBs—we partner with you to engineer success at every stage of your ESDM journey. By combining cutting-edge technology, global resources, and a deep commitment to quality, we help you overcome challenges and deliver products that meet and exceed market expectations.

Need support for your next ESDM project? Contact Aimtron today and experience the difference that expertise makes.

#PCB Assembly#ESDM#Electronics System Design and Manufacturing#PCB Assembly Services#PCB Assembly Solutions#PCB Design

0 notes

Text

Transforming Electronics System Design and Manufacturing: Insights from Aimtron Corporation

In today’s fast-paced technological world, the success of any electronic product depends on robust electronics system design and manufacturing. Aimtron Corporation has positioned itself as a leader in this space, combining innovation, precision, and excellence to redefine how electronic systems are conceptualized and built. With expertise in PCB assembly, electronics design, and end-to-end manufacturing solutions, Aimtron is paving the way for businesses to thrive in a competitive global market.

Revolutionizing Electronics System Design and Manufacturing

At the core of Aimtron’s success is its comprehensive approach to electronics system design and manufacturing. From ideation to production, Aimtron seamlessly integrates advanced technologies with engineering expertise to deliver reliable, high-quality solutions.

What Makes Aimtron’s Approach Unique?

Holistic Design Philosophy Aimtron’s team focuses on understanding the entire product lifecycle, ensuring the design phase aligns with manufacturing realities. This reduces errors, shortens timelines, and optimizes costs.

Integration of Cutting-Edge Technologies Utilizing the latest tools and processes, Aimtron excels in designing and manufacturing complex systems, including IoT devices, automotive electronics, and medical devices.

Customization and Scalability Whether it’s a small prototype or large-scale production, Aimtron’s flexible solutions cater to specific client needs, ensuring scalability without compromising quality.

PCB Assembly: The Backbone of Modern Electronics

Printed Circuit Boards (PCBs) are the foundation of any electronic system, and Aimtron’s state-of-the-art PCB assembly services ensure that every product performs flawlessly.

Key Features of Aimtron’s PCB Assembly Services

Surface Mount Technology (SMT): High-speed, high-precision assembly for compact and complex designs.

Through-Hole Assembly: Durable assembly for products requiring robust mechanical and electrical connections.

Turnkey PCB Assembly: Combining the best of SMT and through-hole assemblies to meet diverse requirements.

Electronics Design: Turning Ideas into Reality

Innovation starts with a strong design, and Aimtron’s electronics design capabilities are second to none. By collaborating with clients and leveraging years of expertise, Aimtron transforms concepts into functional, high-performance electronic systems.

Highlights of Aimtron’s Electronics Design Process

Collaborative Approach Aimtron works closely with clients to understand their goals and translate them into detailed design specifications.

Advanced Prototyping Rapid prototyping ensures that designs are tested and validated quickly, reducing time-to-market.

Focus on Efficiency and Performance Aimtron’s designs prioritize energy efficiency, scalability, and cost-effectiveness without compromising on performance.

How Aimtron Enhances PCB Design for Modern Applications

Aimtron’s PCB design expertise complements its assembly services, ensuring that every board is optimized for its intended application.

PCB Design Innovations at Aimtron

High-Density Interconnect (HDI) Designs: Ideal for compact and advanced electronics.

Thermal Management Solutions: Ensuring heat dissipation for high-performance devices.

Signal Integrity Analysis: Preventing interference and ensuring optimal performance in high-speed applications.

Eco-Friendly Designs: Incorporating sustainable materials and processes.

Industries Transformed by Aimtron’s Expertise

Aimtron’s solutions span multiple industries, addressing diverse challenges and driving innovation:

Automotive Electronics: Advanced driver-assistance systems (ADAS), EV components, and infotainment systems.

Medical Devices: Precision equipment like diagnostic machines and wearable health monitors.

Telecommunications: 5G infrastructure, IoT devices, and network equipment.

Consumer Electronics: Smart home devices, wearable tech, and more.

Why Aimtron Corporation Stands Out

Aimtron’s success in electronics system design and manufacturing is built on a foundation of innovation, customer-centricity, and an unwavering commitment to quality. Here’s why clients choose Aimtron:

End-to-End Solutions From design to delivery, Aimtron handles every aspect of the process.

Global Expertise Aimtron’s global presence ensures access to cutting-edge resources and industry insights.

Sustainability Commitment Eco-friendly practices and materials align Aimtron with modern environmental standards.

Exceptional Support Dedicated teams provide ongoing support to ensure every project is a success.

Conclusion

Aimtron Corporation is more than a manufacturer—it’s a partner in innovation. By combining unparalleled expertise in electronics system design and manufacturing, advanced PCB assembly services, and cutting-edge electronics design, Aimtron empowers businesses to stay ahead of the curve.

#Electronics System Design and Manufacturing#PCB Assembly#PCB Assembly Services#Electronics Design#PCB Design

0 notes

Text

Life Cycle Management

Electronic Manufacturing Services Across the Product Life Cycle

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Design For Excellence (DFX)#Return Merchandise Authorisation (RMA)#BOM Analysis#PLM Agile System For Program Management#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS#Life Cycle-Management

2 notes

·

View notes

Text

Full-Service Medical Device Development with Voler Systems: What You Need to Know

In today’s rapidly evolving healthcare landscape, technology plays a vital role in advancing patient care, diagnosis, and treatment. At the heart of this innovation is medical device product development—an intricate process that blends engineering excellence with strict regulatory compliance. For companies seeking a reliable, experienced partner in this journey, Voler Systems.

With a proven track record of helping clients bring new products from idea to reality, Voler offers a full spectrum of services that span from concept and design through prototyping, testing, and final production. Their deep expertise in sensors, wearable technology, and measurement electronics makes them uniquely qualified to handle the complexities of modern healthcare devices.

As a full-service medical device design consultant, Voler Systems provides tailored R&D solutions for companies that demand precision, quality, and speed. Whether you're developing a wearable heart monitor, a portable diagnostic tool, or a completely new kind of therapeutic device, Voler ensures your product is engineered for success.

One of the key advantages of partnering with Voler Systems is their multidisciplinary team. With engineers and developers who specialize in electrical, mechanical, and software design, the company has the technical know-how to address every aspect of device development. Just as importantly, their team is intimately familiar with FDA regulations and ISO standards. This understanding allows them to navigate compliance efficiently and ensure that every product meets or exceeds industry benchmarks.

Voler’s approach to medical devices development is both collaborative and customer-centric. They work closely with clients to define clear project goals, timelines, and budgets—then execute with precision. Their ability to deliver high-quality, reliable devices on time and within budget has earned them the trust of startups and Fortune 500 companies alike.

Recent projects have included wearable biosensors, home health monitoring devices, and other IoT-connected medical innovations. These breakthroughs demonstrate Voler’s ability to adapt to emerging trends and technologies while maintaining a strong foundation in engineering excellence. Clients appreciate the transparency and flexibility Voler brings to the table, often praising their responsiveness and ability to solve complex challenges quickly.

In addition to technical design and development, Voler also assists with manufacturing hand-off and testing systems. Their robust prototyping and validation services help ensure a seamless transition from design to production. By identifying potential issues early and iterating quickly, Voler helps companies reduce risk and speed time-to-market.

In an industry where accuracy, safety, and speed are critical, Voler Systems delivers unparalleled support and innovation. Whether you're a startup looking to develop your first device or an established brand aiming to modernize your product line, Voler provides the expertise and reliability you need to succeed.

If you're ready to take your medical device concept to the next level, partner with Voler Systems—the trusted choice for full-service medical device product development.

#wearable medical device#electronic design services#projects embedded systems#medical device design#product design electronics#electronics devices manufacturer#medical devices devlopment#Circuit Design Services

1 note

·

View note

Text

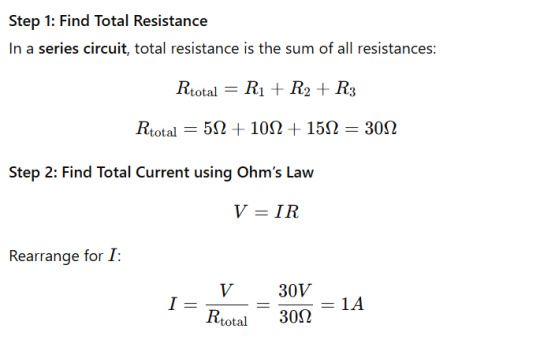

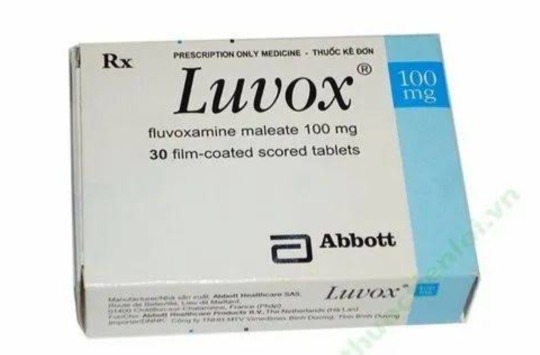

Series Circuit Question

Question: A series circuit consists of three resistors: R₁ = 5Ω, R₂ = 10Ω, and R₃ = 15Ω. The power supply provides 30V. Find: a) The total resistance in the circuit. b) The current flowing through the circuit. c) The voltage drop across each resistor.

LEARN ABOUT ELECTRINICS CIRCUIT | SOLVE THE PROBLEM EASILY.

#high school education#math tips#us school system#education system#free science education#learn about math#learn about physics#learn about science#math study tips#mathematics#electronics prep#electronics components#electronics store#electronics manufacturing#electronics design#electronics industry#appliances

0 notes

Text

#career opportunities in EEE#Electrical and Electronics Engineering#EEE careers#MKCE#M.Kumarasamy College of Engineering#power generation and distribution#electronics design and manufacturing#telecommunications careers#AI in electrical engineering#machine learning in EEE#automation and control systems#research and development in EEE#higher education in EEE#teaching careers in EEE#electric vehicles careers#renewable energy careers

0 notes

Text

Athletes Go for the Gold with NASA Spinoffs

NASA technology tends to find its way into the sporting world more often than you’d expect. Fitness is important to the space program because astronauts must undergo the extreme g-forces of getting into space and endure the long-term effects of weightlessness on the human body. The agency’s engineering expertise also means that items like shoes and swimsuits can be improved with NASA know-how.

As the 2024 Olympics are in full swing in Paris, here are some of the many NASA-derived technologies that have helped competitive athletes train for the games and made sure they’re properly equipped to win.

The LZR Racer reduces skin friction drag by covering more skin than traditional swimsuits. Multiple pieces of the water-resistant and extremely lightweight LZR Pulse fabric connect at ultrasonically welded seams and incorporate extremely low-profile zippers to keep viscous drag to a minimum.

Swimsuits That Don’t Drag

When the swimsuit manufacturer Speedo wanted its LZR Racer suit to have as little drag as possible, the company turned to the experts at Langley Research Center to test its materials and design. The end result was that the new suit reduced drag by 24 percent compared to the prior generation of Speedo racing suit and broke 13 world records in 2008. While the original LZR Racer is no longer used in competition due to the advantage it gave wearers, its legacy lives on in derivatives still produced to this day.

Trilion Quality Systems worked with NASA’s Glenn Research Center to adapt existing stereo photogrammetry software to work with high-speed cameras. Now the company sells the package widely, and it is used to analyze stress and strain in everything from knee implants to running shoes and more.

High-Speed Cameras for High-Speed Shoes

After space shuttle Columbia, investigators needed to see how materials reacted during recreation tests with high-speed cameras, which involved working with industry to create a system that could analyze footage filmed at 30,000 frames per second. Engineers at Adidas used this system to analyze the behavior of Olympic marathoners' feet as they hit the ground and adjusted the design of the company’s high-performance footwear based on these observations.

Martial artist Barry French holds an Impax Body Shield while former European middle-weight kickboxing champion Daryl Tyler delivers an explosive jump side kick; the force of the impact is registered precisely and shown on the display panel of the electronic box French is wearing on his belt.

One-Thousandth-of-an-Inch Punch

In the 1980s, Olympic martial artists needed a way to measure the impact of their strikes to improve training for competition. Impulse Technology reached out to Glenn Research Center to create the Impax sensor, an ultra-thin film sensor which creates a small amount of voltage when struck. The more force applied, the more voltage it generates, enabling a computerized display to show how powerful a punch or kick was.

Astronaut Sunita Williams poses while using the Interim Resistive Exercise Device on the ISS. The cylinders at the base of each side house the SpiraFlex FlexPacks that inventor Paul Francis honed under NASA contracts. They would go on to power the Bowflex Revolution and other commercial exercise equipment.

Weight Training Without the Weight

Astronauts spending long periods of time in space needed a way to maintain muscle mass without the effect of gravity, but lifting free weights doesn’t work when you’re practically weightless. An exercise machine that uses elastic resistance to provide the same benefits as weightlifting went to the space station in the year 2000. That resistance technology was commercialized into the Bowflex Revolution home exercise equipment shortly afterwards.

Want to learn more about technologies made for space and used on Earth? Check out NASA Spinoff to find products and services that wouldn’t exist without space exploration.

Make sure to follow us on Tumblr for your regular dose of space!

2K notes

·

View notes

Text

"As the world grows “smarter” through the adoption of smartphones, smart fridges, and entire smart houses, the carbon cost of that technology grows, too.

In the last decade, electronic waste has become one of the fastest-growing waste streams in the world.

According to The World Counts, the globe generates about 50 million tons of e-waste every year. That’s the equivalent of 1,000 laptops being trashed every second.

After they’re shipped off to landfills and incinerated, the trash releases toxic chemicals including lead, cadmium, arsenic, mercury, and so much more, which can cause disastrous health effects on the populations that live near those trash sites.

Fortunately, Franziska Kerber — a university student at FH Joanneum in Graz, Austria — has dreamed up a solution that helps carve away at that behemoth problem: electronics made out of recyclable, dissolvable paper.

On September 11, Kerber’s invention “Pape” — or Paper Electronics — earned global recognition when it was named a national winner of the 2024 James Dyson Awards.

When she entered the scientific competition, Kerber demonstrated her invention with the creation of several small electronics made out of paper materials, including a fully-functional WiFi router and smoke detector.

“Small electronic devices are especially prone to ending up in household waste due to unclear disposal systems and their small size, so there is significant potential to develop a more user-friendly end-of-life system,” Kerber wrote on the James Dyson Award website.

“With this in mind, I aimed to move beyond a simple recycling solution to a circular one, ensuring long-term sustainability.”

Kerber’s invention hinges on crafting a dissolvable and recyclable PCB board out of compressed “paper pulp.”

A printed circuit board (PCB) is a board that can be found in nearly all modern electronic devices, like phones, tablets, and smartwatches.

But even companies that have started incorporating a “dissolution” step into the end life of their products require deconstruction to break down and recover the PCB board before it can be recycled.

With Kerber’s PAPE products, users don’t need to take the device apart to recycle it.

“By implementing a user-friendly return option, manufacturers can efficiently dissolve all returned items, potentially reusing electronic components,” Kerber explained.

“Rapidly advancing technology, which forms the core of many devices, becomes obsolete much faster than the structural elements, which are often made from plastics that can last thousands of years,” Kerber poses.

PAPE, Kerber says, has a “designed end-of-life system” which anticipates obsolescence.

“Does anyone want to use a thousand-year-old computer?” Kerber asks. “Of course not. … This ensures a sustainable and reliable system without hindering technological advancement.”"

-via GoodGoodGood, September 13, 2024

#ewaste#e waste#e waste recycling#e waste management#e waste solutions#paper#sustainability#green tech#tech news#sustainable technology#recycling#good news#hope

586 notes

·

View notes

Text

A Comprehensive Analysis on Eric Harris, 3.

Disclaimer: This analysis/psychoanalysis is limited only to analysis as a means to reflect and understand the people involved. It is strictly informative. Just like all of my posts, I am detached from the media I write about and solely focus on the people to understand their psychology, for others to gain insight. There is no room for me to romanticize or glorify anything I write because I am only here to explain. I understand and research, but I do not condone. Thank you.

note: This is all solely based on independent research. If I may be wrong with the medical aspects of this post, please correct me. I would appreciate it a lot.

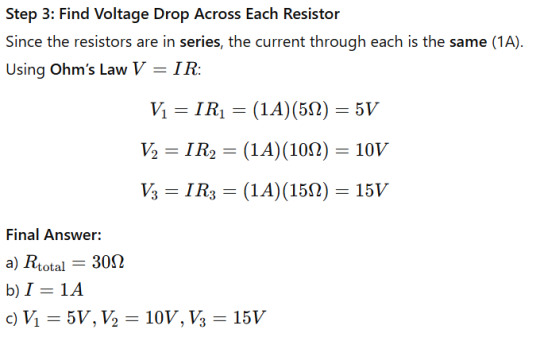

Fluvoxamine Maleate

Just a few days before the shooting, Eric was promptly rejected from his application to serve in the marines. Despite his desirable qualities, he was rejected for the sole reason of being tested positive for consuming a prescripted drug after rejecting that he was off any medication. With a trace of Luvox in his system, theories speculate that the drug's side effects played a role on the events that have transpired. Luvox is a medication prescription drug that is used to treat mental illnesses such as Obsessive Compulsive Disorder (OCD), anxiety, depression, and others. While there are positive effects, the downside are heightened sensations of dread, irritation, depression, and arising violent behaviors. It also has a chance to increase manic symptoms, especially if taken in particularly large doses.

Anti-depressant usage, effects of overdose, and detoxification

When taken over the prescribed dosage, Luvox can lead to increased agression and suicidal ideation and tendencies. Eric was in anger management therapy after being on probation alongside Dylan for attempting to steal a vehicle containing thousands worth of valuable electronics and tools. After getting caught, Eric openly expressed his difficulties in managing his anxiety and explosive anger issues that his counselor said, "he frequently blew up and often cried." Revealing that this influences his homicidal and suicidal thoughts, so he was prescribed Fluvoxamine, which is a selective serotonin reuptake inhibitor (SSRIs). These drugs increase the capacity of the brain to receive serotonin.

According to an interview with Eric's friends, they speculate that Eric was off his medication completely for sometime. Abruptly stopping medication can lead to the development of a more violent response. For some people, drugs are able to fix their chemical imbalances, but it can also lead to withdrawal symptoms of taken for over the duration of 6 weeks. Abruptly discontinuing anti-depressants can lead to rebound depression or relapse. Symptoms may return stronger than before. Furthermore, SSRI's such as Luvox and Prozac take about 5 days to linger in one's system before subsequently washing off.

In a period of 11 months, Eric and Dylan have been under a juvenile detention program at Jefferson County district — this was in 1998, just a year before the shooting. They were allowed to leave the program by early February 1999. After finishing, Eric wrote a letter contained in his juvenile diversion program file. He states, "I learned that thousands of suggestions are worthless if you still believe in violence."

After public demands for stricter regulations on SSRIs after the tragic shooting, Luvox was temporarily banned in 2002. By 2008, drug manufacturers had reformulated Luvox to a controlled-release version specifically designed to treat OCD, excluding indications for depression or anxiety. Subsequently, the FDA approved Luvox CR for the treatment of OCD. The label does not explicitly prohibit prescribing it to the pediatric population, it notes that the smallest dose "may not be appropriate" for children, without providing further explanation.

Eric was about 17 at the time of taking the medication, which means he is part of the pediatric population. Though it's still unclear if he was taking normal doses for a long period of time or taken more than what was prescribed, it is clear that there was negligence with prescribing a child a SSRI that has the posibility of worsening their already apparent symptoms.

Columbine was really a case that opened the public's eyes into the dysfunctional aspects of society and institutions, transcending even to the medical field.

434 notes

·

View notes

Text

𝐀𝐌𝐁𝐄𝐑

1. A hard, translucent fossilized resin, typically yellow, orange, or brown, used for jewellery and ornaments and also in perfumery and traditional medicine.

2. The colour of amber; a (translucent) yellowish-brown or golden colour.

3. figurative. Something which protects something else from disturbance or decay, or which serves to prevent change, movement, or development.

4. Flavoured or perfumed with ambergris; resembling or evoking the smell of ambergris.

5. Frequently with the. Designating an (alcoholic) drink of an amber or light brown colour. Now usually: spec. (chiefly Australian) designating beer, esp. lager. Often in amber fluid, amber liquid.

Words and phrases with "amber"

like a fly (also insect) in amber and variants- used of something permanently preserved, immobilized, or unchanging, or which is regarded as a curious relic of the past.

on (also at) amber: (of a set of traffic lights) showing an amber light; (hence figurative, of a person, proceeding, etc.): unable to progress; temporarily held up or held back.

amberada - Artificial amber used by Europeans for trading in West Africa.

amber alert - Originally Military. A warning that danger, or an emergency, is thought to be near but not actually imminent; an instruction to be prepared for an emergency; (on amber alert) an initial state of readiness to respond to an emergency.

Amber Alert - An announcement that alerts the public to a missing person (esp. an abducted child), disseminated via media broadcasts, electronic roadway signs, etc.; an emergency response system using such announcements.

amber-bush - The head of a young person, typified as a head of bushy, amber-coloured hair

amber-crowned - Having an amber-coloured crown; esp. having a crown of amber-coloured hair.

amber-dropping - That drips amber.

ambered - Originally: flavoured or perfumed with ambergris. Later also: resembling or evoking the smell of ambergris.

ambered sugar - Sugar flavoured with ambergris.

amber-fauna - The insects and other animals of which the remains are found in amber.

amber fishing - The action or practice of dredging for amber at the bottom of the ocean.

amber flora - 1. The plants from which amber is derived.

2. The plants of which the remains are found in amber.

amber forest - The prehistoric forest containing the trees from whose resin amber was formed.

amber gambler - A driver of a road vehicle who accelerates when the traffic lights change from green to amber (instead of stopping, as required by law), gambling that no vehicle will cross his or her path; a driver who starts off when the traffic lights show red and amber together, but not yet green.

ambergris - A wax-like substance having a brownish grey colour and a sweet earthy scent, formed as a natural secretion in the bile duct of sperm whales, and has long been used in perfumery.

amberiferous - Designating a rock or sedimentary deposit containing amber. Also: designating a region in which deposits of amber occur.

amberina .- A type of art glass, originally and chiefly manufactured in the United States in the late 19th and early 20th centuries, having a characteristic two-tone colour, shading from deep red at the top of the piece of glassware to pale amber at the bottom. Also (and in earliest use) more fully amberina glass.

ambering - The action or process of making something amber in colour. Also: the result of this; amber colouring.

amber light - 1. A yellow or amber warning light used to instruct traffic; esp. the middle of three lights in a set of traffic lights, serving as a warning that the signal is about to change to red (stop) or green (go); = yellow light

2. figurative and in figurative contexts. A cautionary indicator or signal; spec. (a) A warning of likely difficulties ahead, requiring heightened caution or vigilance; (b) qualified or tacit permission to proceed in a particular course of action

amber-locked - Having locks of amber-coloured hair.

amber nectar - An alcoholic drink of an amber colour. Now usually: spec. beer, esp. lager.

amber oil -A yellow liquid obtained by distilling amber or (in later use) another resin such as colophony.

amberous - Resembling amber in colour; (translucent) yellowish-brown or golden.

amber pear - A variety of pear said to have a small rounded shape with the scent of ambergris or the scent or flavour of musk (cf. ambrette)

amber plum - Any of several varieties of plum having either a musky flavour or golden skin or flesh.

amber pudding - An open pie or tart consisting of a pastry case with a filling of fruit or (occasionally) puréed, sweetened nuts, with a meringue topping.

amberseed - The fragrant seeds of the musk okra, Abelmoschus moschatus, used as a flavouring and in perfumery. Also called ambrette, musk seed.

amber tree - A prehistoric tree of the kind which produced the resin from which amber was formed.

amber varnish - Varnish made from amber or from a tree resin such as copal.

amber-weeping - That exudes resin; (usually) spec. (Greek Mythology) that weeps tears of amber.

ambery - Resembling amber in colour; (translucent) yellowish-brown or golden.

ambrology - The scientific study of amber.

Things amber often describes (“amber ________”)

eyes, hair, beads, light, glass, dropping, liquid, colour, tree, fish, varnish, fire, oil, bottles, waves, necklaces, brown, yellow, pendants, honey, ornaments, gold, malt, hue, deposits, clouds, glow, objects, glasses, sunlight, grease, satin, smiles, tint, tips, rays, filters, soul, shade, fluid, amulet, violet, wheat, dust, shadow, rosaries, lenses, jewelry, lamps, trinkets, coasts, sand

How amber often is described (“________ amber”)

dark, pale, clear, deep, red, golden, green, white, transparent, rich, pure, black, blue, bright, translucent, soft, warm, true, reddish, polished, fine, grey, thick, powdered, delicate, raw, olive, cloudy, burmese, precious, dull, fossil, burnt, pink, clouded, brilliant, opaque, cretaceous, gray, genuine, artificial, coral, finest, thin, crystal, faint

you can support me on Patreon

#dark academia#langblr#spilled ink#words#spilled words#english language#vocabulary#writebrl#resources for writers

72 notes

·

View notes

Text

What Makes Aimtron Electronics a Leader in ESDM and PCB Assembly?

In today’s fast-paced world of electronics manufacturing, companies are constantly looking for ways to innovate, streamline operations, and improve the quality of their products. One company that stands out in this space is Aimtron Electronics, a leader in the field of Electronics System Design and Manufacturing (ESDM) and PCB (Printed Circuit Board) Assembly. But what sets AImtron apart from its competitors?

Let’s explore the key factors that have helped Aimtron Electronics become a trailblazer in the ESDM and PCB assembly industries.

1. Comprehensive End-to-End ESDM Solutions

Aimtron Electronics offers a complete range of services that span the entire product lifecycle, from initial concept to final delivery. This end-to-end capability allows the company to provide tailored solutions that meet the unique needs of its clients. Whether it's designing a custom PCB, developing complex electronics systems, or providing full-scale manufacturing, Aimtron integrates each step seamlessly, ensuring quality and efficiency throughout the process.

This ability to handle every phase of the development cycle means clients don't have to manage multiple vendors, which can lead to miscommunication, delays, and inconsistencies. Aimtron’s holistic approach not only simplifies the process but also accelerates time-to-market, which is crucial in today’s competitive electronics landscape.

2. Cutting-Edge PCB Assembly Technology

Aimtron Electronics has built a reputation for using the latest technology and techniques in PCB assembly. The company invests heavily in advanced manufacturing equipment, including pick-and-place machines, automated optical inspection (AOI) systems, and reflow soldering technology. These innovations ensure that each PCB assembly is completed with the highest level of precision and reliability.

Moreover, Aimtron’s facilities are designed to handle a wide range of PCB assembly types, including single-sided, double-sided, and multi-layer boards. This versatility means that the company can meet the needs of a variety of industries, from consumer electronics to automotive and industrial applications.

3. Uncompromising Quality Control Standards

One of the hallmarks of AImtron Electronics is its commitment to quality. The company adheres to strict industry standards, such as ISO 9001 and IPC-2221, ensuring that its products meet or exceed the highest benchmarks in the ESDM and PCB assembly industries. AImtron integrates quality control (QC) at every stage of the production process, from design to final assembly.

To further ensure the reliability of its products, AImtron employs automated testing systems, in-circuit testing (ICT), and functional testing to detect any potential defects early in the process. These rigorous quality control measures reduce the likelihood of failure and improve the overall performance of the final product.

4. Design Expertise and Innovation

At Aimtron, the design team is at the heart of everything. The company’s engineers are experts in Electronics System Design (ESD), with deep knowledge in a wide variety of industries and applications. AImtron’s design capabilities cover a broad spectrum, including analog circuits, digital circuits, RF (Radio Frequency) designs, and power electronics.

The team works closely with clients to understand their unique needs and provide innovative solutions that align with their business goals. This collaborative approach ensures that each design is optimized for performance, manufacturability, and cost-efficiency. Additionally, Aimtron’s design team uses state-of-the-art CAD (Computer-Aided Design) software to create accurate and detailed schematics, reducing the likelihood of errors and streamlining the design-to-manufacturing transition.

5. Scalability and Flexibility

Aimtron Electronics excels in delivering scalable solutions. Whether a customer needs a small batch run for prototyping or high-volume production for large-scale manufacturing, Aimtron has the capacity and flexibility to meet diverse demands. The company’s manufacturing facilities are designed for scalability, enabling it to accommodate both small and large orders with equal efficiency and quality.

This flexibility is particularly beneficial for clients in industries such as medical devices, telecommunications, automotive, and aerospace, where demands can fluctuate based on market conditions, regulations, and technological advancements.

6. Commitment to Sustainability

As industries increasingly focus on reducing their environmental footprint, Aimtron Electronics has taken significant steps to ensure that its operations are both efficient and eco-friendly. The company actively embraces green manufacturing practices, such as reducing waste, recycling materials, and utilizing energy-efficient technologies in its PCB assembly process.

Aimtron also works with clients to develop environmentally friendly products, ensuring that their designs are not only high-performing but also sustainable. This commitment to sustainability resonates with clients who are looking to reduce their carbon footprint and meet global environmental standards.

7. Customer-Centric Approach

Aimtron’s customer-centric approach is one of the key factors that sets it apart from other companies in the ESDM and PCB assembly space. From the initial consultation to after-sales support, Aimtron places a strong emphasis on building lasting relationships with its clients.

The company offers personalized service, ensuring that each customer’s unique needs are met with tailored solutions. Aimtron’s engineering team works hand-in-hand with clients to refine designs, troubleshoot issues, and optimize product performance. Additionally, the company’s customer service team is always available to provide ongoing support, from product updates to maintenance and repair services.

8. Global Reach with Local Expertise

While Aimtron Electronics operates on a global scale, it combines this reach with local expertise to serve a diverse client base across multiple industries. The company’s team understands the nuances of different markets, from regional regulations and certifications to cultural considerations in manufacturing.

Aimtron’s ability to navigate these complexities while delivering top-tier ESDM and PCB assembly services has earned the company a strong reputation as a trusted partner in the global electronics supply chain.

Conclusion

Aimtron Electronics stands out as a leader in Electronics System Design and Manufacturing (ESDM) and PCB Assembly due to its combination of cutting-edge technology, rigorous quality standards, innovative design expertise, and a customer-focused approach. The company’s commitment to excellence, scalability, and sustainability has positioned it as a trusted partner for companies across a variety of industries.

With a strong emphasis on precision, efficiency, and reliability, Aimtron Electronics continues to push the boundaries of what’s possible in electronics manufacturing, ensuring that its clients remain competitive in an ever-evolving market.

If you're looking for a partner who can handle all your ESDM and PCB assembly needs, Amitron Electronics offers the experience, technology, and customer care you need to succeed.

#Electronics System Design and Manufacturing (ESDM)#PCB Assembly#Electronics System Design#functional testing#automated optical inspection#reflow soldering#ESDM Solutions

0 notes

Note

What materials is Biohazard made of? I guess not everything resists radiation

Indeed! No material is totally resistant to radiation; it always depends on the amount of radiation and the exposure time.

Let me get a little nerdy

I clarify and repeat: I'm not an expert on the subject. I did research for this AU in general and thus determined the right materials for the construction of Biohazard. I may be wrong. But this is sci-fi, and some things are improbable but intentional, like Biohazard's melting rays!

Endoskeleton and joints: titanium alloys, stainless steel, and aluminum reinforced with carbon fiber.

Internal components:

Microchips and components: specifically designed to withstand high doses of radiation and encased in a dense layer of ceramic material within a tungsten protective box.

Sensors made with materials resistant to radiation and high temperatures. Integrated into the endoskeleton and protected by a dense covering material.

Actuators: electric or hydraulic motors made with corrosion- and wear-resistant materials. Located within the joints and protected by the endoskeleton.

Metallic lithium-Ion batteries specially designed to operate in extreme environments, housed in a tungsten protective box, away from sensitive components.

Cooling system: copper tubes and non-flammable, radiation-resistant cooling fluids integrated into the endoskeleton to dissipate heat generated by electronic components and shielding.

Protection systems:

Primary shielding: lead sheets and boron-based composite materials, 1.5 centimeters thick.

Secondary/Exterior shielding: tungsten sheets, 1 cm thick.

Biohazard has numerous limbs and components functioning as redundant systems. In the event of a failure, he can continue operating with backups.

He used to integrate cameras and sensors for remote monitoring and data collection. These are no longer operational.

Being made of very dense materials, he's extremely robust and heavy! You practically couldn't lift one of his arms if he were off!

He was very, very expensive to manufacture as well. The frustration was very great when the project "didn't work".

#long post#Biohazard oc#GC Biohazard#Gamma Code AU#Gamma Code fic#GC concepts#fnaf eclipse#fnaf sun#fnaf moon#sundrop#moondrop#fnaf dca fandom#dca community#fnaf#fnaf security breach#security breach#five nights at freddy's#beloved moot#asks

124 notes

·

View notes

Text

Oregon governor Tina Kotek yesterday signed the state's Right to Repair Act, which will push manufacturers to provide more repair options for their products than any other state so far.

The law, like those passed in New York, California, and Minnesota, will require many manufacturers to provide the same parts, tools, and documentation to individuals and repair shops that they provide to their own repair teams.

But Oregon's bill goes further, preventing companies from implementing schemes that require parts to be verified through encrypted software checks before they will function, known as parts pairing or serialization. Oregon’s bill, SB 1596, is the first in the nation to target that practice. Oregon state senator Janeen Sollman and representative Courtney Neron, both Democrats, sponsored and pushed the bill in the state senate and legislature.

“By eliminating manufacturer restrictions, the Right to Repair will make it easier for Oregonians to keep their personal electronics running,” said Charlie Fisher, director of Oregon's chapter of the Public Interest Research Group, in a statement. “That will conserve precious natural resources and prevent waste. It’s a refreshing alternative to a ‘throwaway’ system that treats everything as disposable.”

Oregon's law isn't stronger in every regard. For one, there is no set number of years for a manufacturer to support a device with repair support. Parts pairing is prohibited only on devices sold in 2025 and later. And there are carve-outs for certain kinds of electronics and devices, including video game consoles, medical devices, HVAC systems, motor vehicles, and—as with other states—“electric toothbrushes.”

Apple opposed the Oregon repair bill for its parts-pairing ban. John Perry, a senior manager for secure design at Apple, testified at a February hearing in Oregon that the pairing restriction would “undermine the security, safety, and privacy of Oregonians by forcing device manufacturers to allow the use of parts of unknown origin in consumer devices.”

Apple surprised many observers with its support for California's repair bill in 2023, though it did so after pressing for repair providers to mention when they use “non-genuine or used” components and to bar repair providers from disabling security features.

According to Consumer Reports, which lobbied and testified in support of Oregon's bill, the repair laws passed in four states now cover nearly 70 million people.

272 notes

·

View notes

Text

The robotics industry should be creating robots that could be reprogrammed and repurposed for other tasks once its life span is completed, University of Bristol and University of West England researchers have advised. The study, published by Towards Autonomous Robotic Systems, aims to challenge individuals working in the robotics industry and in academia to note the effect that their early work can have on the long-term use of a robotic system. With 80% of a robots environmental impact decided during the initial design phases of a product life-cycle, experts argue it is essential that researchers, designers and manufacturers understand the limitations of recycling an electronic product at the end of its life, and instead consider the other options possible to move products and the industry towards a sustainable life-cycle.

Read more.

24 notes

·

View notes

Text

Cadillac was founded in 1902 by Henry Leland, who named the company after Antoine de la Mothe Cadillac, who happens to be the founder of Detroit. Just 6 short years later Cadillac brought the idea of interchangeable parts to the automotive industry and laid the ground work for modern mass production of automobiles. As a result, Cadillac became the first American car to win the prestigious Dewar Trophy from the Royal Automobile Club of England. After earning such high praise Cadillac adopted the slogan "Standard of the World."

In 1910, Cadillac became the first company to offer a passenger car with a fully enclosed cabin, a major change from the vehicles of the time. Two years after that, in 1912, the company released the Model Thirty, the car with no crank, which was the first production car to feature an electronic self-starter, ignition, and lighting. By dropping the crank starter, Cadillac opened the door to women drivers, and was able to bring the prestigious Dewar trophy back to Detroit, making Cadillac the only car manufacturer to claim the award twice. Nearly three years later, Cadillac brought the world the V-type, water-cooled, eight cylinder (V8) engine, which would become the signature of the Cadillac brand.

The Roaring 20's was not only a big decade for the country but was also important for Cadillac. In 1926, Cadillac branched out and offered customers more than 500 color combinations to choose from. As the famous Henry Ford saying goes, you can have any color you want, as long as it's black. Cadillac changed this mentality. That same year, the company brought in designer Harley Earl to design the 1927 LaSalle convertible coupe, which made the car the first to be designed from a designer's perspective rather than an engineering one. What Earl created was elegant, with flowing lines, chrome-plate fixtures, and an overarching design philosophy, that made the Cadillac brand known for beauty and luxury.

In the middle of the 1930's a midst The Great Depression, while most companies and families were struggling Cadillac created the first V-type 16-cylinder engine for use in a passenger car. This engine would go on to be one of the most iconic engines in Cadillac history. Shortly thereafter, Cadillac released a V12 version to give buyers something between the already popular V8 and new V16 engines.

Cadillac went quiet in the 1941's when they suspended automobile production to help produce planes for the war. After the war ended Cadillac adapted some of the aircraft technology and created the first ever tailfin on a vehicle. This feature is now found on almost every car and was one of the biggest reasons that Cadillac was given the first ever Car of the Year award in 1949.

The tailfin took off rather quickly and by the mid to late 1950's it was being featured heavily in the design of nearly every vehicle. Also in the 50's Cadillac began developing power steering, which helped the automaker take third, tenth, and eleventh places at the 24 Hours of Le Mans. After Cadillac's stunning "victories" power steering quickly became the new standard of the industry.

Small but meaningful innovations filled the 1960's for Cadillac. In 1963, the company made front seatbelts standard in their vehicles, which lead to the eventual passing of a federal law requiring front seatbelts in all vehicles just one year later. Then, in 1964, Cadillac brought to market automatically controlled headlamps and redefines luxury with Comfort Control, the industry's first thermostatically controlled heating, venting, and air-conditioning system. Over the next few years, Cadillac introduced variable-ratio power steering, electric seat warmers, and stereo radio.

While the 1960's were fairly quiet, with only some smaller, luxury items being introduced, Cadillac started out 1970 with a major bang. Cadillac opened the decade by unveiling the 400 horsepower, 8.2-liter engine Eldorado. With its completely redesigned axle this model boasted the highest torque capacity of any passenger car available at the time. Closing out the decade, Cadillac brought to market the 1978 Seville which used onboard microprocessors in its digital display. This started the era of the computerized automobile.

Throughout the 1980's Cadillac laid low, working on some new technologies that would come to market in the early parts of the 1990's. The first feature to debut was an electronic traction control system on front-wheel drive vehicles. Cadillac began offering this as a standard feature on the 1990 Cadillac Allante. This same year Cadillac would go on to win the Malcolm Baldrige National Quality Award. Two years later, in 1992, the company developed a feature that allowed the engine to run for up to 50 miles without coolant, and a unique induction system for near-perfect fuel distribution. The Seville Touring Sedan of that year would become known as the "Cadillac of the Year" thanks to features such as an all electronically controlled Powertrain, traction control, anti-lock brakes and speed-sensitive suspension. Closing out the decade, Cadillac introduced the, now iconic, Escalade SUV.

CELEBRATING 100 YEARS AS 'THE STANDARD OF THE WORLD'

Coming up on the 100th anniversary of the Cadillac brand, the company had to do something big or the decade, and they did not disappoint. Cadillac started off the 200's by introducing the F-22 stealth aircraft inspired Cien Concept, which ended up winning a few design awards. Later in the decade, in 2008, Cadillac expanded the Escalade SUV by making it the world's first full-size luxury hybrid SUV. In the same year, the company redeveloped the CTS Sedan. This redesign has been incredibly popular and even won the coveted 2008 Car of the Year award. A short year later, the performance edition CTS-V, becomes the fasted V8 production sedan in the world, establishing a record lap time of 7:59:32 on Germany's famed Nürburgring.

#cadillac#cadillac eldorado#cadillac fleetwood#cadillac deville#cadillac coupe de ville#Cadillac escalade#car#cars#Cadillac Escalade SUV

69 notes

·

View notes

Text

Turkina 'Ghostbird'

(mini by u/VersusJordan)

Mass: 95 tons Chassis: JF X-Composite Power Plant: 285 JF Extralight Cruising Speed: 32.4 kph Maximum Speed: 54 kph Jump Jets: Standard Jump Capacity: 90 meters Armor: JF Ferro-Fibrous Armament: 52.0 tons of pod space Manufacturer: Complex Beta, Olivetti Weapons Primary Factory: Ironhold, Sudeten Communication System: JF Integrated w/ Neutron Star CEWS Targeting & Tracking System: Series JFIX/Olivetti Pinpoint Advanced Introduction Year: 3153 Tech Rating/Availability: F/X-X-X-X Cost: 34,525,969 C-bills

Overview The Turkina is a powerful OmniMech that was first seen in the Turkina Keshik at the Battle of Tukayyid, and entered general service with Clan Jade Falcon following the end of the Refusal War. This specific Turkina was constructed in late 3151 on Sudeten, and assigned to Star Commander Alexis Zarnofsky by personal order of Jiyi Chistu, then Khan of the Jade Falcon Remnants. Named by Alexis to share her 'Ghostbird' callsign, the 'Mech would rapidly find use in repelling Hell's Horses attacks on Sudeten.

Capabilities By 3153, Alexis' personal configuration, based off an upgraded Prime config, is armed for mid-to-long range combat with twin ER PPCs, LRM-15s (with Artemis V FCS), and Light Autocannon/10s, offering increased firepower and accuracy over the base Prime variant. Five extra double heat sinks and a Radical Heat Sink System keep heat manageable, while enough ammunition is mounted to keep the Turkina in the fight for extended periods. In addition, the legs and feet of the 'Mech have been reinforced and fitted with integrated talons, making for deadly kicks and Death from Above attacks. A Neutron Star CEWS system ensures that Star Commander Alexis can stay in contact with her Starmates, while provided electronic warfare capabilities. In keeping with common Star League design specifications, Ghostbird has had its cockpit reduced in size, fitted with control customized to Alexis' exact ergonomic considerations, and then armored, while additional armor was placed over the head area.

Deployment Ghostbird is the personal 'Mech of Alexis Zarnofsky, and thus has deployed with her on all operations where Zarnofsky has taken part.

History Alexis and Ghostbird have seen significant service - initially in the defense of Sudeten against various foes of the Jade Falcon Remnant forces in the Hinterlands. In October of 3152, Clan Hell's Horses would launch an attack on Sudeten, their second that year. Nearly overwhelmed in the defense of Hammarr, Star Commander Alexis was preparing for a last stand with her Khan, Jiyi Chistu, and other members of the Clan. Just as the situation seemed hopeless, the Jade Falcon Remnants were suddenly and unexpectedly reinforced by a joint force consisting of forces from Clan Jade Falcon, Wolf, Ghost Bear, Smoke Jaguar, Snow Raven, and Sea Fox, the SLDF's Royal Black Watch, and elements of the Northwind Highlanders. Under the command of SLDF Brevet Commanding General Melissa Hazen and arriving via a suborbital drop, the combined reinforcements confused and routed the Hell's Horses, saving the Falcons of Sudeten. During this battle, Alexis would account for ten enemy 'Mechs killed by her own hand, with another five shared, and three probables. After the battle, she would be promoted to Star Captain by personal order of Melissa Hazen, and be personally selected to serve alongside both her former Khan (now saKhan) Jiyi Chistu and Khan Stephanie Chistu in the command Star of the Turkina Keshik.

Type: Turkina Technology Base: Mixed (Unofficial) Tonnage: 95 Battle Value: 2,906

Equipment Mass Internal Structure Composite 5 Engine 285 XL 8.5 Walking MP: 3 Running MP: 5 Jumping MP: 3 Double Heat Sink 16 [32+7+4] 6 Compact Gyro 4.5 Small Cockpit (Armored) 2 Armor Factor (Ferro) 293 15.5 Internal Armor Structure Value Head 3 9 Center Torso 30 45 Center Torso (rear) 15 R/L Torso 20 30 R/L Torso (rear) 10 R/L Arm 16 32 R/L Leg 20 40

Weight and Space Allocation Location Fixed Space Remaining Head None 2 Center Torso Jump Jet 3 Right Torso 2 XL Engine 6 4 Ferro-Fibrous Left Torso 2 XL Engine 9 Ferro-Fibrous Right Arm 2 Double Heat Sink 8 Left Arm 2 Double Heat Sink 8 Right Leg Jump Jet 0 Ferro-Fibrous Left Leg Jump Jet 0 Ferro-Fibrous

Right Arm Actuators: Shoulder, Upper Arm Left Arm Actuators: Shoulder, Upper Arm

Weapons and Ammo Location Critical Heat Tonnage Radical Heat Sink System (Armored) CT 3 - 4.0 Artemis V FCS RT 2 - 1.5 Double Heat Sink RT 2 - 1.0 LRM 15 RT 2 5 3.5 2 LAC/10 LA 8 3 16.0 Artemis V FCS LT 2 - 1.5 CASE II LT 1 - 0.5 LRM 15 Artemis V-capable Ammo (16) LT 2 - 2.0 LRM 15 LT 2 5 3.5 Caseless LAC/10 Ammo (40) LT 2 - 2.0 Armored Cowl (Armored) HD 1 - 1.0 Nova Combined Electronic Warfare System (Armored) HD 1 - 1.5 2 Double Heat Sink RA 4 - 2.0 2 ER PPC RA 4 15 12.0

Features the following design quirks: Accurate Weapon (all), Battle Computer, Combat Computer, Cowl, Easy to Pilot, Extended Torso Twist, Improved Communications, Improved Cooling Jacket (all), Improved Sensors, Multi-Trac, Nimble Jumper, Reinforced Legs, Variable Range Targeting, Illegal Design (overweight; mounts Talons without weight and space needed)

10 notes

·

View notes